INTRODUCTION OF QUALITY OF TABLETS

AND CAPSULES

Experiment 1 : Uniformity of diameter, thickness and hardness

Tablets and

capsules are common dosage form of drugs. As we know that in the production of

tablets mostly, the tablets itself does not only contain the active ingredients

of the drug but it also consists of adjuvants such as the binding agent,

glidant, disintegrant, lubricants and etc. The purpose of adding the adjuvants

is to ensure the stability, uniformity and the function of the drugs to a

maximum level which then perhaps will produce the best quality of tablets. Same

goes to capsules also as it just differ from tablets in terms of coating. There

are two types of capsules that are hard capsules and soft capsules.

For hard

capsules it consists of powdered while for soft capsules normally consists of

liquid. The coated capsules itself is made up from gelatin normally. In British

Pharmacopoeia and United State Pharmacopoeia had set such a standard on

uniformity of diameter, uniformity of weight, content of active ingredient,

uniformity of content, disintegration and dissolution. Moreover there are also

have number of quality control procedures but there is no info about the

non-pharmacopoeias (thickness, hardness and friability).

Thus, we had

conducted some experiments to demonstrate the application of a number of

selected physical dosage performance test on tablets and capsules sample.

Experiment 1 : Uniformity of diameter, thickness and hardness

Objective :

To test uniformity on diameter, thickness and

hardness of the tablets with Tablet Testing Instrument.

Date : 12 December 2013

Introduction

:

Among different choices of routes of administration, oral dosage forms

like tablets and capsules are usually the most convenient choice as it’s the

simplest and easiest way for any patient to take a medication. Tablets are made of a compressed

powdered substance containing an active drug and excipients while capsules

refer to small soluble container which is usually made of gelatin that encloses

a dose of an oral medicine or vitamin. There are a number of quality control procedures which are

non-pharmacopoeial standards carried out such as the uniformity of diameter,

thickness and hardness to ensure the efficiency the delivery of drugs. Tablets

are used in the following experiment. Uniformity of the diameter and hardness of tablet

follows the pharmacopoeial standard and is used for uncoated and

coated tablets whereas the thickness test is not found in pharmacopoeia. The

uniformity of diameter test is not applicable to enteric-coated, film coated

and sugar coated tablets. All these tests can be completed using the instrument

PHARMATEST

PTB 311.

Materials and

Apparatus :

Paralgin tablets, PHARMATEST PTB 311(Tablet Testing Instrument)

Procedures :

1.

10 tablets were selected and tests for

uniformity of diameter, thickness and

hardness were carried out using the Tablet Testing Instrument

(PHARMATEST PTB 311).

2.

The deviation of individual unit from the

mean diameter should not exceed ±5% for tablets with diameter of less than

12.5 and ±3% for diameter of 12.5 mm or more.

Results and Calculations :

Tablet

|

Diameter (mm)

|

Thickness (mm)

|

Hardness (N)

|

1

|

13.12

|

5.38

|

140.58

|

2

|

13.12

|

5.41

|

153.37

|

3

|

13.11

|

5.45

|

154.44

|

4

|

13.12

|

5.44

|

148.57

|

5

|

13.11

|

5.45

|

165.63

|

6

|

13.15

|

5.46

|

150.53

|

7

|

13.12

|

5.39

|

158.70

|

8

|

13.12

|

5.45

|

143.24

|

9

|

13.13

|

5.47

|

167.77

|

10

|

13.11

|

5.43

|

158.67

|

Mean

|

131.21/10=

13.12

|

54.33/10

=

5.43

|

1541.51/10=

154.15

|

Percentage of deviation from mean diameter (%) =

Mean of diameter for the tablets– Diameter of each tablet

Mean diameter for the

tablets

Percentage average of

deviation for diameter of each unit:-

Tablet 2 :0%

Tablet 3: 0.08%

Tablet 4: 0%

Tablet 5: 0.08%

Tablet 6: 0.23%

Tablet 7: 0%

Tablet 8: 0%

Tablet 9: 0.08%

Tablet 10: 0.08%

Discussion :

Based on the data

obtained, the mean diameter of all the tablets is 13.12mm and all these tablets

with diameter of more than 12.5mm does not exceed ±3% for the deviation of

each unit from their mean diameter. The uniformity of diameter of tablet is

included in pharmacopoeial standard. According to the pharmacopoeial standard,

the deviation of each tablet from the mean diameter should not exceed ±5% for

tablets with diameter of less than 12.5mm and ±3% for diameter of 12.5 mm or

more which means all the tablets tested in the experiment are qualified as

their diameter is within the standard range. The slight deviations of diameter

of the tablets might be caused by the uneven feeding of granules into die or may be due to

the irregular movement of lower punch as the die and punches determine the

diameter and shape of tablet.

For the test

of uniformity of thickness and hardness, both of these test are not under

pharmacopoeial standard previously. However, uniformity of hardness test has

been newly added to pharmacopoeial standard. These are parts of a

manufacturer’s own product specification. Any variation

in thickness within a particular lot of

tablets or between manufacturer’s lots should not be clear to the naked eye for

consumer acceptance and it should be controlled to facilitate the

progress of packaging. The thickness may vary with no change in weight due to

difference in the granulation and pressure applied to the tablets, wear and

tear on length of punches as well as on the speed of tablet compression.

The hardness

test on tablets should be conducted to determine the rate and

extent to which active ingredient is absorbed and becomes available at the site

of action and to ensure the tablets possess sufficient mechanical strength and

resistant force to withstand mechanical shock during handling in production,

packaging, distribution and storage. This is because hardness of tablet also

can affect its disintegration. If the tablet is too hard, it may not

disintegrate in the required period of time. If the tablet is too soft, it

could not withstand the handling during subsequent processing such as coating

and packaging.

If the tablets batch do not obey these test in real manufacturing

process, the manufacturer will remanufacture the tablets by modifying the ingredients used

whether in amount of ingredients or change the types of ingredients. This is to

ensure only drugs with good properties and good quality control will be

supplied to patients.

Conclusion :

The tablets tested have

uniform diameter, thickness and hardness and they are under the range of standard

properties required.

References :

- Kibbe, A.H., ed. Handbook of Pharmaceutical Excipients. 3rd Edition ed. 2000, American Pharmaceutical Association & Pharmaceutical Press, Washington, DC & London, UK.

- http://www.pharmainfo.net/tablet-evaluation-tests/content-uniformity

- http://www.scribd.com/doc/59995285/11-Evaluation-of-Tablets

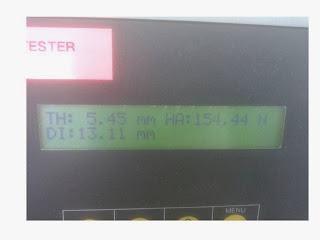

Paralgin

tablets

Testing of uniformity of diameter,thickness and

hardness of tablet

Data

shown by PHARMATEST PTB 311

No comments:

Post a Comment